Hunter Advantage

- Over 15k placements

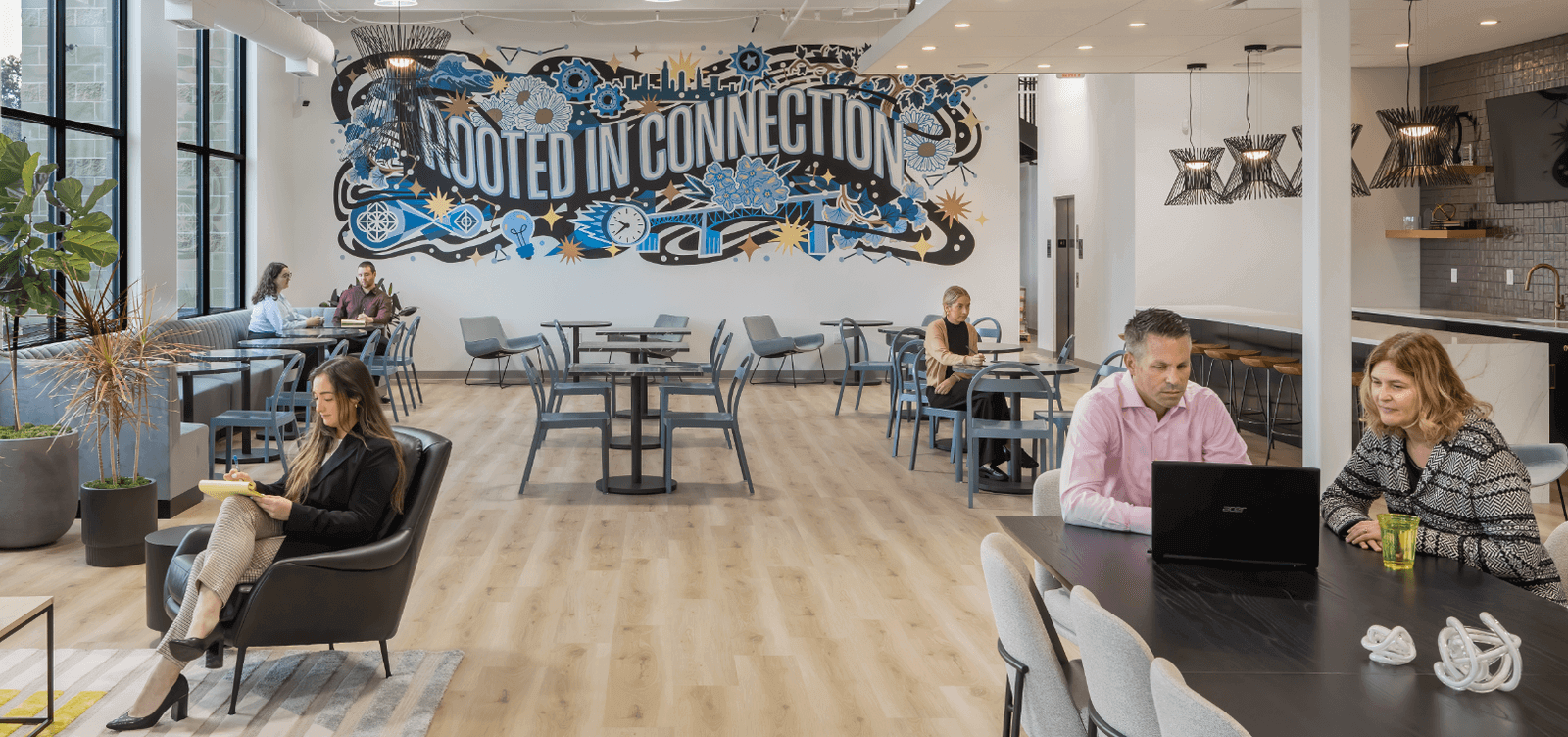

- Rooted in connection

- Based in the USA

- Flexible work nationwide

View details

View details

View details

View details

View details

View details

View details

View details

View details

View details

Recruiting agency in STEM

20 years of experience in STEM, healthcare, manufacturing, and more.

Retention rate

of candidates from job satisfaction of applicants and employers.

of new hires

report career growth and professional development within first 18 months.

Upload your resume and a recruiter will be in touch!

Here’s the latest blogs to help you with your staffing and job search!

Resources to help you land a new job, tips to advance your career and industry insight from our expert team – all sent to your inbox.